1.Airflow type non-destructive particles, powder automatic running mixing equipment

2.No dead angle, no leakage, sealed and mixed environment

3.No passive pollution, no major mechanical parts maintenance costs

4.Quick mixer (mixing takes only a few minutes)

5.Large-capacity mixer, homogenization bin (several tens of tons or more, homogenization and mixing equipment)

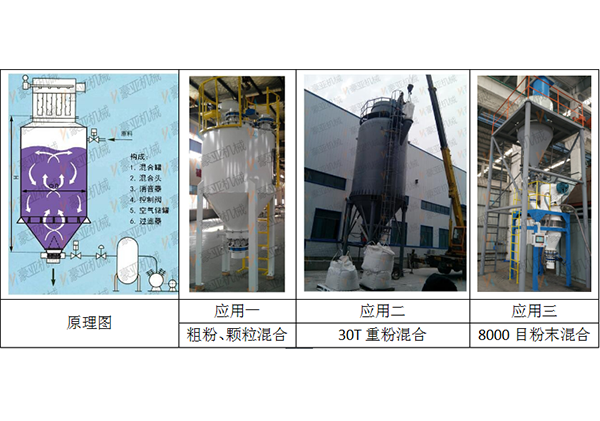

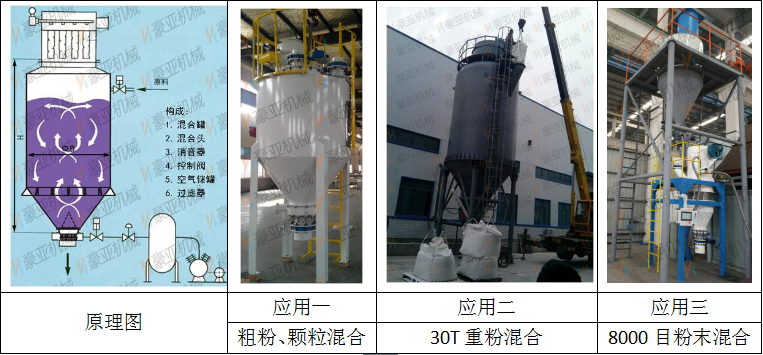

First, the principle:

When the air stored in the bottom of the mixer is instantaneously sprayed, the powder and granules in the can turn into a boiling state, and the mixture is thoroughly stirred and mixed. The injected air is discharged by the upper air filter. Spraying for a short period of time and consuming very little compressed air allows for thorough mixing and high efficiency. Combined with raw material transportation, the introduction of touch screen and PLC control, it is very convenient to set up an automatic processing line for raw materials.

Second, the characteristics:

1. Quick mix large capacity

A batch of materials can be mixed evenly in a few minutes, and the mixing can be from several tons to several tens of tons at a time, and the mixing operation cost is saved.

2. No dead angle design

It can be applied to medicines, foods, etc. without hollow holes or negative corners.

3. There is no mechanical rotating part in the mixer

There is no friction and heat generation, and there is no case where the lubricant contaminates the product. Because there is no agitation, it can be mixed without loss, such as chicken essence, compound fertilizer particles and the like. It is especially suitable for the mixing of fine powders, and it does not get stuck in rotating machinery such as bearings, etc., and has no trouble for a long time.

4. Closed mixing, no dust and environmental protection

5. Easy to use, free to set, automatic operation.

6. Feeding and discharging is convenient.

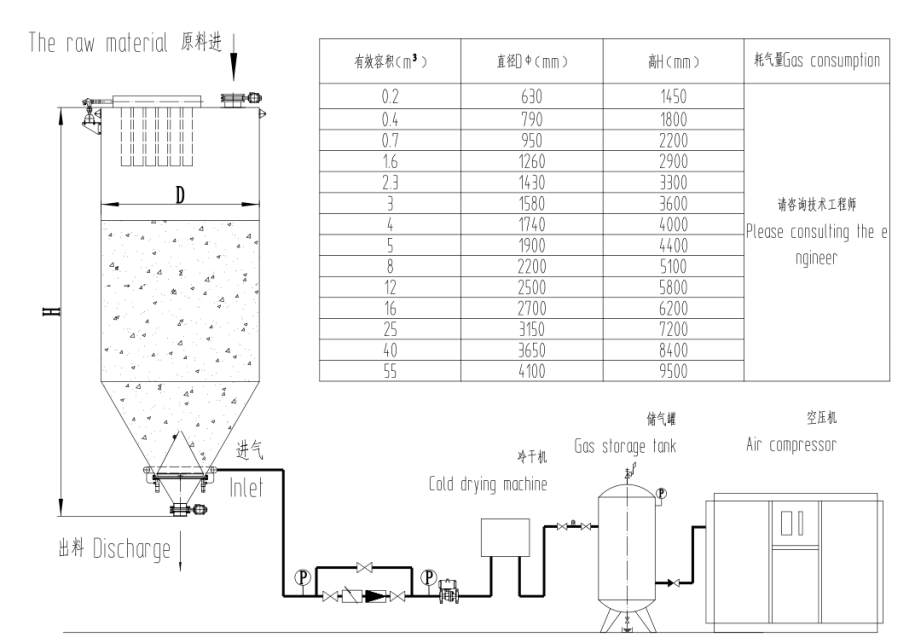

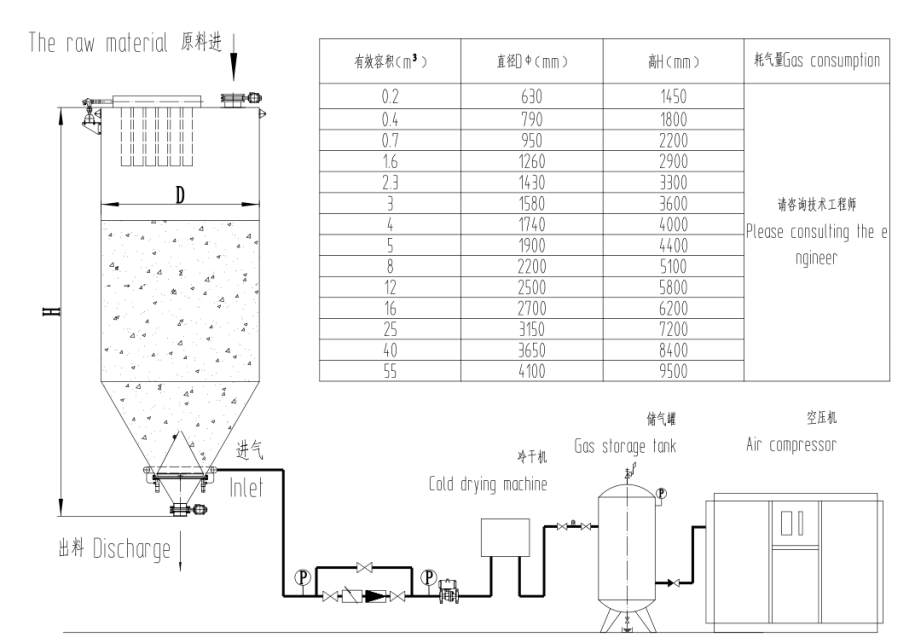

Third, technical parameters:

Compressed air operating pressure (Mpa) 0.8 to 1.5

Mixing time (minr) 3~5

Loading factor 0.4~0.6

Working temperature (°C) atmospheric pressure

Working pressure inside the cylinder (Mpa)

Fourth, the application:

This equipment is mainly used in chemical products, plastics, pharmaceuticals, electronic substrates, food, feed, cement, earth and stone, ceramic raw materials and other industries with homogeneous requirements, rapid and large capacity mixing.